Two fundamental systems are available for the fabrication of awnings and canopies: the Sewn System and the Staple-in System. Both are composed of a skeletal frame and a membrane (fabric) cover. Each system has been used extensively in the past; however, the staple-in system has made rapid technological advancements to become the preferred method within the industry.

Two fundamental systems are available for the fabrication of awnings and canopies: the Sewn System and the Staple-in System. Both are composed of a skeletal frame and a membrane (fabric) cover. Each system has been used extensively in the past; however, the staple-in system has made rapid technological advancements to become the preferred method within the industry.

Staple-in System

Sign 2000 produces complete custom awning and canopy frame systems utilizing the "staple-in" method of fabric attachment. See Stapling Concept below for a complete description of the staple-in method.

.jpg) The system features many structural aluminum extrusions, and the steel staple-in structural tubing,.

The system features many structural aluminum extrusions, and the steel staple-in structural tubing,.

All are available in stock lengths, which can be cut, formed, and welded into a variety of frame configurations ranging from standard awning and canopy shapes to the most custom and innovative fabric structure designs, each is limited only by the designers imagination. Framing can be used either in the natural mill finish or it can be painted. The welded frames can be covered with most any brand of commercial or industrial  fabric

fabric

|

|||||

|

|

We carry a large collection of classic canvas awnings and canvas canopies to add protection from the elements and lower energy costs. These affordable fabric awnings and fabric canopies will be custom-made to your order.

SAVE Money!! SAVE Energy!!

Limited 5-Year Frame and Fabric Manufacturer Warranty. |

||||

|

View the embedded image gallery online at:

http://signof2000.com/index.php/sign-products-services/awnings-canopy/stationary-awning#sigProId0f1f3390e5

|

|||||

Eradicable, Flexible Sign and Awning Membrane

20 ounce

This membrane features a scrim design that is nearly invisible to allow for maximum light diffusion, consistent translucency, and brilliant colors in backlit signs and awnings.

Treated with anti-wick, ultraviolet stabilizers, fungicides, whitener for excellent color protection, durability, and long life.

Roll Width: 6?6? (78")

Roll Length: Available in 10, 25, or 50 yards

Sold: Cut yardage, price per yard

Available Colors:

Cooley-Brite Lite Eradicable Fabric

Eradicable, Flexible Sign and Awning Membrane

16 ounce

This membrane?s light weight offers unique flexibility for simple installation. It is translucent, flexible, durable, and features excellent lay-flat characteristics. Engineered for high color brilliance and consistent color translucency.

Perfect for eradication, screen printing, and pressure-sensitive applications. Cooley-Brite Lite is ideal for staple system installations. Advanced scrim design enhances graphic effects to provide superior quality and luminescent colors.

Roll Width: 6?6?

Roll Length: available in 10, 25, or 50 yards

Sold: Cut yardage, price is per yard

Cooley

Cooley-Brite? II with Coolthane

Eradicable, Flexible Sign and Awning Membrane

20 ounce

This top-of-the-line membrane possesses all the advantages of our colored Cooley-Brite and more. It features the added protection of our Coolthane formulation, which enhances cleanability and extends the life of the product to eight years.

Roll Width: 6?6?

Roll Length: Available in 10, 25, or 50 yards

Sold: Cut yardage, price per yard

Available Colors:

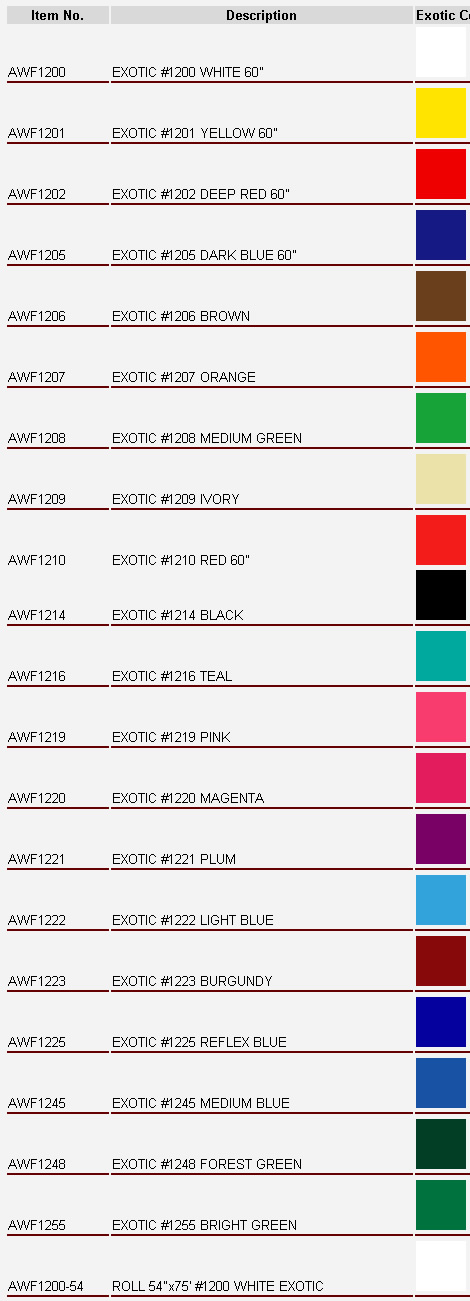

Exotic Plus

Exotic Plus 16 oz. Back-Lit Fabric

The Exotic Plus? is the most beneficial and top of the line back-lit fabric in the

The Exotic Plus? is the most beneficial and top of the line back-lit fabric in the

- Glass smooth surface, allows easy and high bond of vinyl and paint graphics without bubbling or peeling.

- 80" Wide material creates seamless awnings with less waste and decreased labor time.

- Acrylic top coat greatly enhances outdoor durability, reduces cracking and ambrittlement, adds strength, retains flexibility, protects against color fading and staining, and allows material to be cleaned easily of dirt & grime etc.

- 12 Designer colors the finest vinyl is used to provide rich color when illuminated with back lighting, and there is no loss of day-light appearance.

Rolls are 80" Wide, 16 ounces per square yard. Put up on 25 yard rolls.

Sold in full rolls or cut yardage.

Actual swatch book color chart is available. Please call us or contact your sales rep.

Specifications:

Weight: 16oz/Yard

Thickness: 22 Mill

Width: 80"

Roll Size: 25 Yards

Acrylic Topcoat: Yes

Light Transmission (%): 22 - 24

Tensile Strength (lbs): 260 x 175

Tearing Strength (lbs): 35

Heat Resistance (180c 5 minutes): Pass

Cold Resistance (-30c): Pass

Mildew Resistance: Yes

Fungus Resistance: Yes

Flame Resistance: Yes

Approvals:

California Fire Marshal: Pass # FA51206

N.Y.C. Dept. of Buildings (MEA): Pass # 221-02-M

Warranty:

A 6 year pro rata warranty covering cost of material for excessive loss of color or strength, under normal conditions.

Technical & Warranty

|

|

Staple-in is the revolutionionary fabric awning construction method that replaces needle & thread with STEEL STAPLES. |

|

with LOTS of items in the "plus" column:

|

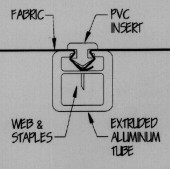

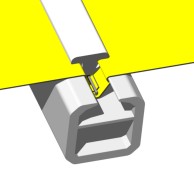

The awning frame is made of lightweight, square aluminum extrusions that have an open channel on one side, with a thin, aluminum webbing in the center. The selected awning fabric is then cut to size, then STAPLED (with a pneumatic stapler) directly to the aluminum channel inside the extrusion. Excess fabric is then trimmed, and a complimentary or contrasting PVC trim bead is driven into the channel, covering the staples. The awning frame is made of lightweight, square aluminum extrusions that have an open channel on one side, with a thin, aluminum webbing in the center. The selected awning fabric is then cut to size, then STAPLED (with a pneumatic stapler) directly to the aluminum channel inside the extrusion. Excess fabric is then trimmed, and a complimentary or contrasting PVC trim bead is driven into the channel, covering the staples.

This creates an incredibly TIGHT AWNING COVER Frames Frames for sewn awnings and canopies are constructed from a wide variety of materials and methods, making them less standardized. Because of this, their quality will vary greatly depending on the fabricator and the geographical region. The frame joints can be made with fittings, bolts, screws and welds. Of all these, welding is the most common.

Frames for staple-in awnings and canopies are always constructed with a specialized collection of aluminum extrusions, which are cut to appropriate miters and then welded together. The staple-in system is highly uniform in comparison with the older sewn system, and is less affected by changes in geographic region or skill level. Covers are made from a wide selection of fabrics. Due to recent advancements in fabric technology, awning and canopy covers now have expected life spans exceeding 10 years. A thorough review of these fabrics and their characteristics are covered in the Fabric Selection Guide. It is highly recommended that you read that section carefully before selecting a fabric for your cover. The sewn system is characterized by one-piece fabric covers. It is a two step cover attachment method in which the cover is made first, then attached to the frame as a separate step. The one-pieced covers are made by sewing (or heat welding) individual fabric panels together. The frame attachment is achieved by a system of laces along the cover's edge that tie the cover to lace-bars. Because sewn covers are one piece, they are usually quite large, and require folding for transport. Since some fabrics cannot be folded without causing permanent damage, the sewn system limits fabric selection.

The staple-in system is characterized by aluminum frames to which covers are attached by way of stapling. More information on how the staples hold the fabric to the frame is given on this section. The staple-in system is a one step cover attachment method because it joins fabric panels together and attaches them to the frame simultaneously. This method is proven to be the most efficient and durable way to attach awning and canopy covers, and accommodates all varieties of fabrics. Because of its wide use and popularity with manufacturers, the staple-in attachment method is the focus of this manual. Most written specifications for fabric structures call for the fabricator to show code compliance and to guarantee structural integrity. Although this is a standard practice, it is highly recommended that the architect investigate these matters early in the design phase of the building. Most awning and canopy fabrication shops are unfamiliar with structural analysis and the advanced procedures related to local, state, and national code compliance. Where structural analysis is required to show compliance, it is highly recommended that the structural engineer for the building project also perform the calculations for the awning or canopy frame. This helps coordinate the loads from the fabric structure into the building's structural calculations. It is best for the engineer to work directly with the awning and canopy fabricator to develop a frame that is both structurally sound, and within the standard construction practices of the fabricator. Warranty: Fabric & Frame

|

Care and Cleaning

One of the best ways to keep Sunbrella� fabrics looking good and to delay the need for deep or vigorous cleanings is to hose fabrics off on a monthly basis with clear water. This practice will help prevent dirt from becoming deeply embedded in the fabric and eliminate the need for more frequent vigorous cleanings. In most environments, a thorough cleaning will be needed every two to three years.

When it's time for a thorough cleaning, Sunbrella fabrics can be cleaned while still on an awning frame or, size permitting, they can be removed for cleaning in a washing machine.

When cleaning Sunbrella fabrics, it is important to observe the following:

- Always use a mild soap such as Ivory Snow, Dreft or Woolite.

- Water should be cold to lukewarm. Never more than 100�F.

- Air dry only. Never apply heat to Sunbrella fabrics.

- General or Light Cleaning

- To clean Sunbrella while still on an awning frame, follow these simple steps:

- Brush off loose dirt.

- Hose down.

- Prepare a cleaning solution of water and mild soap such as Ivory Snow, Dreft or Woolite (no detergents).

- Use a soft bristle brush to clean.

- Allow cleaning solution to soak into the fabric.

- Rinse thoroughly.

- Air dry.

- May not require retreatment depending on the age of the fabric.

- If stubborn stains persist, you can use a diluted chlorine bleach/soap mixture for spot cleaning of mildew, roof run-off or other similar stains (see our Stain Chart for specific

- recommendations).

- Heavy Cleaning for Stubborn Stains and Mildew

- Sunbrella fabric does not promote mildew growth, however, mildew may grow on dirt and other foreign substances that are not removed from the fabric. To clean mildew, or other

- stubborn stains:

- Eight ounces (1 cup) of chlorine bleach.

- Two ounces (1/4 cup) of mild soap and/or detergent.

- One gallon of water.

- Clean with soft bristle brush.

- Allow mixture to soak into fabric for up to 20 minutes.

- Rinse thoroughly.

- Air dry.

- Repeat if necessary.

- Retreatment of fabric for water and stain resistance will be necessary.

- Remember to protect the area around your Sunbrella if using a bleach solution. Carpet or other fabrics that are not Sunbrella may have an adverse reaction to the bleach.

- If an awning is suitable in size for a washing machine, these steps should be followed:

- Use mild soap and/or detergent.

- For heavier stains add 1 cup of bleach to wash.

- Wash and rinse in cold water.

- Air dry. Never apply heat to Sunbrella.

- Retreatment for water and stain resistance will be necessary after machine washing.

Retreating the Fabric

- As part of the finishing process, Sunbrella fabrics are treated with a fluorocarbon finish, which enhances water repellency. This finish is designed to last for several years, but must be replenished after a thorough cleaning. Based on test results, Glen Raven recommends 303 High Tech Fabric Guard? as the preferred retreatment product for Sunbrella fabrics.

- Fabrics should be retreated after thorough cleaning or after five years of use. For more information on retreatment products, please visit www.303products.com. Applying 303 High Tech Fabric Guard 303 should be applied to Sunbrella fabrics after each thorough cleaning, which typically removes the original finish and reduces the fabric's water repellency.

- Clean Sunbrella fabric, using one of the cleaning methods.

- Allow Sunbrella to completely air dry.

- Apply 303 Fabric Guard in a well-ventilated area following instructions on the container.

- Apply 303 in a thin, even coat and allow fabric to dry completely.

- Apply a second thin, even coating of 303. (Two light coatings are more effective in restoring fabric water resistance than a single heavy coating. A 15-ounce bottle provides coverage of up to 50 square feet of fabric.)

- For more information please see www.303products.com.

- Professional Awning Cleaners

- You may have access to professional awning cleaning firms. In evaluating the services of a professional firm, you should inquire about a firm's experience in working with Sunbrella fabrics and knowledge of cleaning and retreatment requirements. DO NOT dry clean Sunbrella fabrics.

Helpful Hints

- Protect the area around the Sunbrella fabric when using a bleach solution - bleach may discolor non-Sunbrella fabrics. Always rinse Sunbrella thoroughly to completely remove bleach.

- Sunbrella air dries very quickly. Machine drying is not necessary.

- If fabric has some wrinkling, use an iron, if necessary, but only on the synthetic* setting. As some irons exceed the recommended 100�F temperature on the synthetic setting, test a small inconspicuous area before ironing entire piece.

-

DO NOT use a steamer or iron set to steam setting.

-

Use of bleach and/or advanced age of the fabric application may impact the deterioration of the sewing thread and other non-Sunbrella components.

* Synthetic fabric heat settings normally do not exceed 150�F.

damaged

damaged Awnings Warranty:

Awnings Warranty: